AUTOMATION SCADA & IOT Solutions

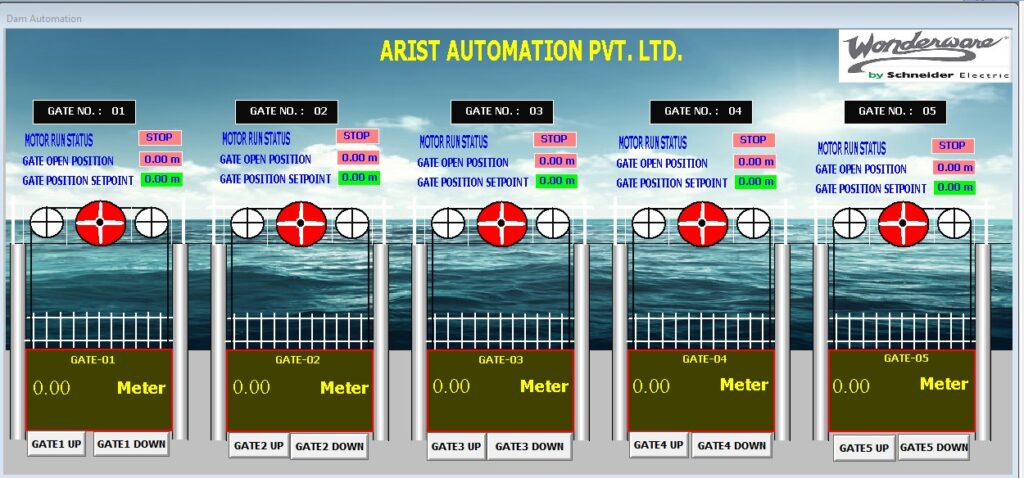

DAM Gate SCADA and Automation

Cloud Based IOT solutions

Benefits of Barrage/Dam Automation

- Centralized Monitoring & controlling of Barrage/ Dam operations ensures development of Reliable Decision Support System with better response time.

- Improved water management by getting accurate data of Dam/Barrages and its subsidiary canals.

- Accurate and reliable measurement of discharge ensures improved efficiency of Irrigation system.

- Reduction in human intervention minimizes Operational errors.

- Remote monitoring of Barrage/Dam system will ensure the better supervision from management level

Cloud based Real Time Machine monitoring system

Production Managment System

Energy Managment system

Predictive maintenance system

CNC Monitoring system

We are Proudly

Associated With

Arist Automation - Industrial Automation, PLC Training & Services

We Provide

Industrial Solution & Training

Training

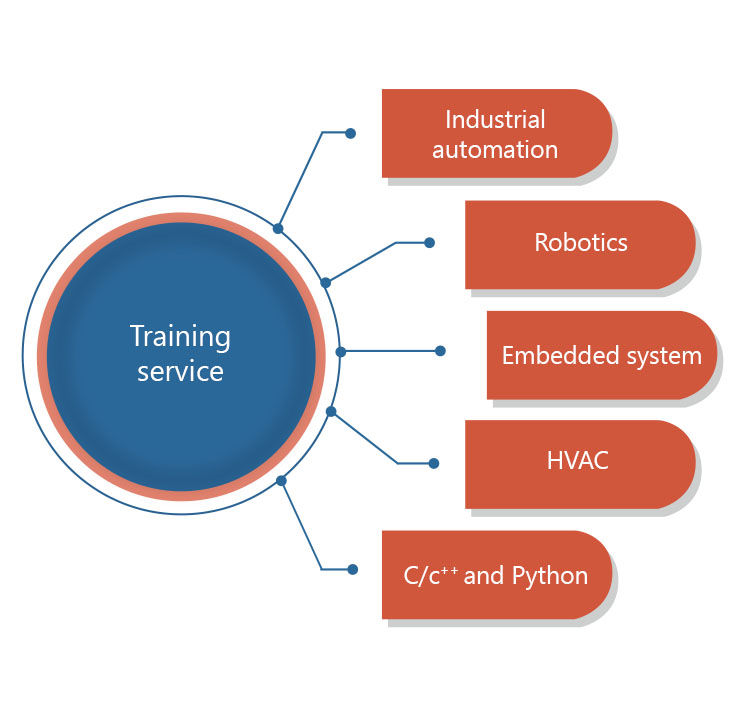

We provide training on Industrial Automation, Robotics, Embedded System, C/C++, Python, Java, HVAC and PLC Training in Indore & Bhopal.

Industrial Projects

We provide industrial solution to our esteemed customers specializing in Wireless Automation, Industrial IOT and Lora Wan technology, PLC Programming, Scada & Industrial Automation.

Placements

We have dedicated placement support team that goes extra mile to support you in your career with industry-specific placements.

Why you should select

Arist Automation

We are One-Roof-Solution for all your needs related to Industrial Automation, Embedded Systems & PLC Training and Services.

TRAINING

INDUSTRIAL PROJECT

PLACEMENT

Our Services

Rely on our experts to automate your Industrial processes!

Arist automation is a leading name in Industrial Automation projects and services in Central India. We work on turnkey projects and provide best solution for machine automation.

From consulting to design, implementation, monitoring, maintenance, safety and training services. Our team of experienced certified experts delivers holistic Industrial Automation programs to ensure that your plants and equipment are well-designed, operated safely and properly maintained. We are a premier institute for PLC training in Indore and Bhopal

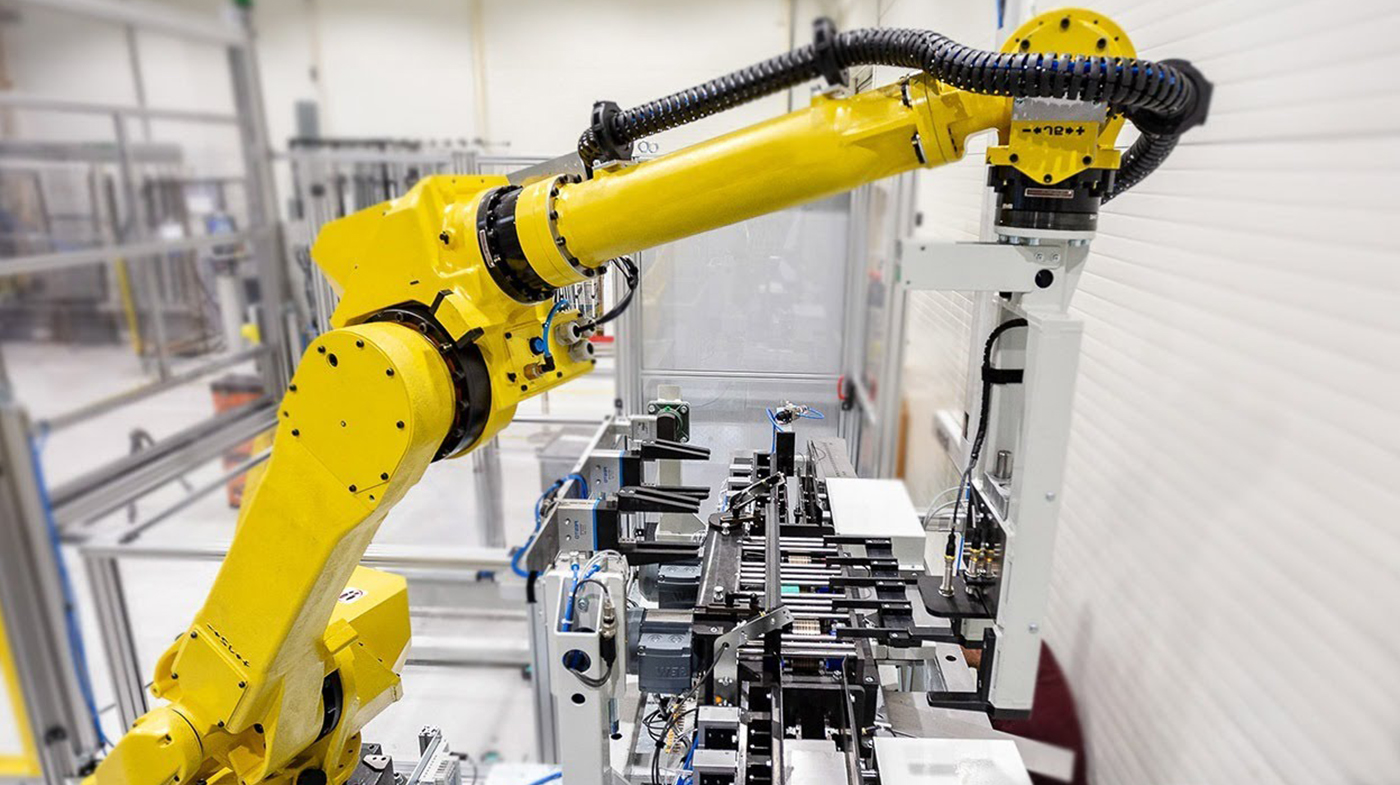

We Conceptualize, Plan, Design, Build and Deploy high quality, cost-effective Panel designing solutions in the field of mechatronics, Industrial Automation & Robotics. With our long track record of delivering excellent solutions, we can help you meet your automation, testing & custom engineering needs.

Our Robotics Automation helps you achieve faster ROI with full featured robotic process automation (RPA). RPA helps in automating routine tasks to increase operational efficiency by over 95% and reduce 75% of manual efforts and your employees can increase their productivity by working on critical tasks.

Arist Automation offers superior solutions in IIoT to help you automate more business and IT processes and enable you to achieve digital transformation.

Arist IIoT solution enables industrial companies of various sizes to link their machines, products, plants, systems and enabling you to harness the wealth of data generated by the Internet of Things (IoT) with advanced analytics.

Since last 8 years, Arist Automation has been serving electronic industry for customized automation solution & developments. This includes Industrial Automation of existing machinery, firmware development for Wireless technology. We ensure all systems are always up-to-date, maximize asset performance by reducing downtime and increasing performance levels, also provide added value, and maximize system utilization.

Training We Offer

Automation & Industrial IOT

PLC

COMMISSIONING

PLC system is the significant key in the innovation and world turn of events .We provide PLC training in Indore & Bhopal with job placement.

Robotics involves design, construction, operation, and use of robots. We at Arist Automation provide one of the best Robotics training.

SCADA DEVELOPMENT

The basic SCADA architecture begins with Programmable logic controllers(PLC) or remote terminal units. Join our best SCADA PLC training course with 100% placement.

Our Valuable

Customers

Meet our

Team members

XYZ

Instrumentation & Design Solution

Shubham Soni

Engineer

Anjali

Automation Engineer

Aman Patel

Bhopal Center Head

We are Proudly

Working on

From the blog

Latest News

DAM gate SCADA system

Posted by adminDAM SCADA and Automation Major components of DAM SCADA PLC as per IEC 62443-4-1 standard & has international certification of Achilles Certification Level II. Gate Position Measuring System Water Level Sensors. IP based Bullet cameras and PTZ cameras User authentication, user-based SCADA software with Server system & Large LED display with NIC Certification UPS/DG Power

+ Read More

100% Job Oriented Industrial Automation Training Program | Job Oriented Industrial Automation Training In India | 100% Job Oriented Industrial Automation Training In Indore | 100% Job Oriented Industrial Automation Training In Bhopal

Posted by admin100% Job Oriented Industrial Automation Training Program | Job Oriented Industrial Automation Training In India | 100% Job Oriented Industrial Automation Training In Indore | 100% Job Oriented Industrial Automation Training In Bhopal

BEST PLC SCADA TRAINING INSTITUTE IN INDIA | PLC SCADA COURSE FEES WITH CERTIFICATE | PLC SCADA COURSE DURATION | PLC SCADA TRAINING GOVT INSTITUTE

Posted by adminPLC SCADA TRAINING WITH 100% PLACEMENT ASSISTANCE India’s Leading PLC SCADA and Industrial Automation Training Institute in Indore and Bhopal Arist Automation PLC SCADA Course Fees With a Certificate for “Industrial Automation” brings strong experience and knowledge to India in association with MSME, Established in the year 2014, Arist Automation is a registered and privately

+ Read More

Incoming Tags – Industrial automation course in Indore, Industrial automation course in Bhopal, PLC Training in Indore, PLC Programming Course, PLC Training in Bhopal, Best PLC Training institute in Indore & Bhopal.